Understanding Injection Robots and Their Applications

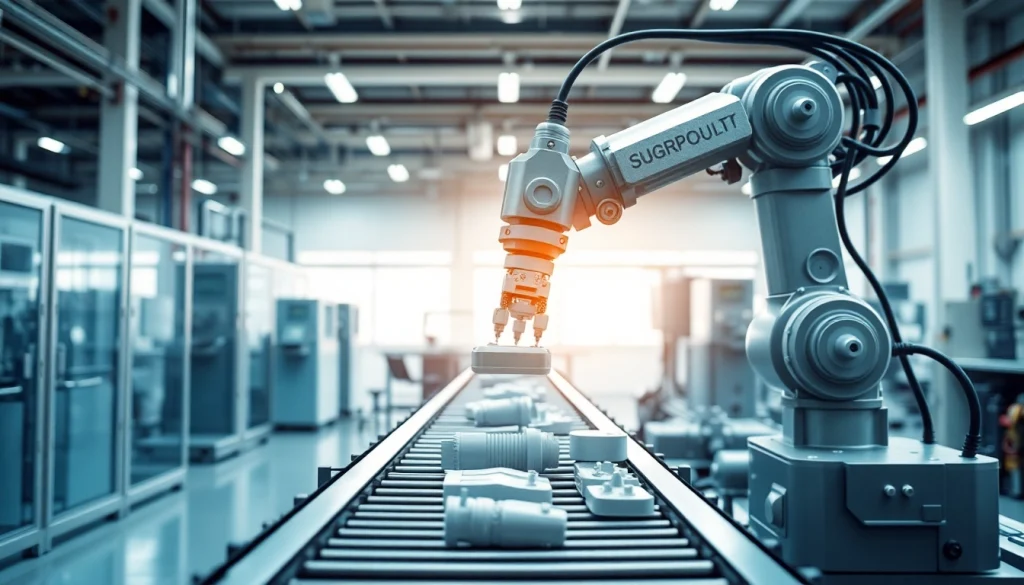

Injection robots have become pivotal in modern manufacturing, particularly in the plastic injection molding process. These advanced machines are designed to automate various tasks involved in the production of molded parts, enhancing efficiency, precision, and overall productivity. When exploring options, Injection Robot systems offer comprehensive insights into the latest technologies and methodologies set to improve your production line.

What is an Injection Robot?

An injection robot is a programmable machine that automates the retrieval and handling of molded parts during the injection molding process. Typically integrated with injection molding machines, these robots can perform tasks such as removing parts from molds, assembling components, and packaging finished products. Their design can include various configurations such as SCARA (Selective Compliance Assembly Robot Arm), Cartesian, and six-axis robots, each suited for different manufacturing environments.

Key Functions of Injection Robots in Manufacturing

Injection robots are equipped to perform a multitude of tasks that streamline the production process, including:

- Pick and Place: Extracting formed products from molds and placing them in designated areas.

- Quality Inspection: Conducting automated inspections to ensure that the produced parts meet quality standards.

- Assembly: Integrating additional components into the molded parts for a complete assembly.

- Packaging: Preparing and packaging the final products for shipment, enhancing efficiency in logistics.

Common Industries Utilizing Injection Robots

Various industries leverage injection robots to enhance productivity and ensure high-quality output. Some of the most common sectors include:

- Automotive: For producing complex parts with high precision.

- Consumer Goods: Manufacturing everyday items like containers, toys, and appliances.

- Medical: Creating sterile components necessary for medical devices and packaging.

- Electronics: Assembling delicate components where precision is crucial.

Benefits of Implementing Injection Robots

Enhanced Efficiency and Productivity

The implementation of injection robots results in significantly enhanced efficiency. These machines operate at a speed and accuracy that surpasses manual labor, ultimately leading to faster production cycles. For instance, a typical robot can complete the pick-and-place function in a matter of seconds, reducing cycle times and increasing overall throughput.

Cost Reduction Through Automation

Automating the injection molding process with injection robots can lead to substantial cost savings. While the initial investment may seem significant, the long-term reduction in labor costs, decrease in material waste, and lower rates of defects contribute to a return on investment that justifies the expenditure. For high-volume production runs, the cumulative savings can be considerable.

Improved Quality Control and Consistency

Injection robots provide a level of consistency that is difficult to achieve with human operators. Automated systems minimize the risk of human error, leading to more uniform products. Enhanced quality control measures are often integrated into these systems, allowing for real-time monitoring and adjustments to maintain standards throughout the production process.

Choosing the Right Injection Robot for Your Needs

Evaluating Different Types of Injection Robots

When selecting an injection robot, it is essential to evaluate the specific needs of your operation. Considerations include the size and complexity of the parts being produced, the desired production speed, and the available space in your facility. Different robot types offer unique advantages, so aligning these with your production goals is key.

Key Features to Consider

Important features to consider when choosing an injection robot include:

- Payload Capacity: Ensure the robot can handle the weight of the parts it will manipulate.

- Speed: Look for robots that can achieve fast cycle times without sacrificing accuracy.

- Software Compatibility: The robot should seamlessly integrate with existing manufacturing software for ease of programming and operation.

- Service and Support: Consider the availability of technical support and spare parts from the manufacturer.

Budgeting for Your Injection Robot Investment

Budgeting for an injection robot involves not only the upfront purchase cost but also ongoing operational costs such as maintenance, software updates, and training for staff. It’s also vital to consider the potential cost savings generated through productivity increases and reduced labor costs over time.

Challenges and Solutions in Using Injection Robots

Common Misconceptions About Injection Robots

Many manufacturers have misconceptions about injection robots, particularly concerning their complexity and cost. The notion that robots are only for large-scale operations deters smaller businesses from exploring automation. In reality, advancements in technology have made injection robots more accessible and cost-effective for a wider range of applications.

Addressing Technical Difficulties and Risks

Like all machinery, injection robots can encounter technical difficulties. Ensuring that staff are adequately trained in troubleshooting can mitigate downtime. Furthermore, developing a regular maintenance schedule can help prevent unexpected failures and prolong the lifespan of the robots.

Best Practices for Successful Integration

Successful integration of injection robots into a manufacturing environment requires careful planning and execution. Here are some best practices:

- Involve Key Stakeholders: Engage everyone from management to floor workers in the automation process.

- Pilot Testing: Run a pilot program to identify potential issues before full implementation.

- Training: Provide comprehensive training to ensure all users are competent in operating and troubleshooting the robots.

Future Trends in Injection Robot Technology

Innovations to Expect by 2025

As we look towards 2025, advancements in injection robot technology are expected to continue at a rapid pace. Innovations such as enhanced machine learning algorithms will allow robots to learn and adapt to changing operational conditions, improving efficiency and reducing error rates. Additionally, collaborative robots (cobots) designed to work alongside human operators will gain traction, providing flexibility in production environments.

Sustainability in Injection Molding Automation

Sustainable practices will increasingly influence the direction of injection molding automation. Companies are seeking ways to reduce their environmental impact, from using eco-friendly materials to minimizing energy consumption during the molding process. Injection robots will play a vital role in optimizing these processes, thereby enhancing sustainability throughout the manufacturing chain.

The Role of AI and Machine Learning in Robotics

The integration of artificial intelligence (AI) and machine learning into injection robots is set to revolutionize manufacturing. These technologies will enable robots to analyze data in real-time, predict maintenance needs, and optimize workflows. As AI becomes more pervasive, manufacturers will benefit from smarter, more responsive systems capable of handling increasingly complex tasks.