Understanding the Basics of dxf Files

When embarking on any laser cutting project, having a clear understanding of dxf file for laser cutting is essential. These files serve as the backbone of most laser cutting operations, as they provide a vector-based format that accurately represents your design. Whether you’re in the crafts, prototyping, or manufacturing sector, knowing how to leverage DXF files effectively is crucial for successful outcomes.

What is a dxf file for laser cutting?

A DXF (Drawing Exchange Format) file is a CAD (Computer-Aided Design) data file format developed by Autodesk for enabling data interoperability between AutoCAD and other software applications. DXF files contain 2D and 3D drawings, making them ideal for laser cutting tasks, where precision and accurate representation of complex designs are vital. Essentially, the DXF files guide the laser cutter on where to cut, engrave, or mark the material.

Common Uses and Applications

DXF files are widely used across various industries for laser cutting applications. Some common uses include:

- Architecture: Creating models and prototypes of buildings and structures.

- Industrial Design: Designing parts and components for machinery and equipment.

- Art and Crafts: Producing intricate patterns and designs for artwork, jewelry, and decorative items.

- Signage: Crafting custom signs, logos, and branding materials.

- Prototyping: Developing functional prototypes for consumer products quickly.

Advantages of Using dxf Files

The use of DXF files in laser cutting offers several advantages, including:

- Precision: DXF files ensure exact dimensions and intricate details in designs.

- Interoperability: They can be used across various CAD software, enhancing workflow efficiency.

- Speed: Facilitating rapid design adjustments, leading to faster turnaround times in production.

- Accessibility: Users can easily share and modify DXF files, promoting collaboration among teams.

Preparing Your Design for Laser Cutting

Design preparation is an essential step before any successful laser cutting project. Here’s how you can ensure your designs are ready for cutting.

Software Options for Creating dxf Files

Choosing the right software is vital for creating quality DXF files. Popular CAD software options that support DXF file creation include:

- AutoCAD: A leading CAD software known for its robust tools and features.

- Inkscape: An open-source vector graphics editor perfect for crafting intricate designs.

- Adobe Illustrator: A widely-used graphic design software with excellent DXF export capabilities.

- CorelDRAW: A vector graphic design software that is user-friendly and effective for laser cutting.

Tips for Designing Efficiently

Efficiency in design can impact the final output of your laser cutting project. Here are some tips:

- Use Layers: Organize different components of your design using layers to streamline the cutting process.

- Optimize Paths: Simplify paths to reduce cutting time, which can enhance productivity.

- Avoid Small Details: Ensure that intricate details align with the capabilities of your laser cutter to avoid issues during cutting.

- Test Cuts: Perform test cuts on inexpensive material before finalizing your design on the actual material.

Exporting Your Design as a dxf File

Once your design is finalized, exporting it as a DXF file requires careful attention to settings:

- Select the desired elements in your design software.

- Navigate to the export option in the file menu.

- Choose DXF as the file format and adjust export settings as necessary.

- Save the file and verify its compatibility with the laser cutter’s software.

Choosing the Right Laser Cutting Equipment

Selecting the appropriate laser cutting equipment is pivotal for the success of your projects. Here’s what you need to consider.

Types of Laser Cutters

There are several types of laser cutters available, each suited for different applications:

- CO2 Laser Cutters: Best for cutting non-metal materials such as wood, acrylic, and leather.

- Fiber Laser Cutters: Ideal for cutting metals, offering higher cutting speeds and efficiency.

- YAG Laser Cutters: Suitable for high-precision applications, particularly in industrial settings.

- Green Laser Cutters: Effective in marking and engraving, particularly on plastics and metals.

Key Features to Consider

When choosing a laser cutter, consider the following features:

- Power: Higher wattage translates to faster cutting speeds and the ability to cut thicker materials.

- Cutting Area: Ensure the bed size aligns with the maximum dimensions of your projects.

- Software Compatibility: Check if it supports the DXF file format and integrates seamlessly with your design software.

- Cooling System: A robust cooling system is essential for maintaining performance during prolonged use.

Budgeting for Equipment

Budgeting is crucial when acquiring laser cutting equipment. Here are some considerations:

- Initial Costs: Account for the purchase price, delivery, and installation costs.

- Operational Costs: Include expenses such as maintenance, power consumption, and material costs for projects.

- ROI Analysis: Consider potential income from completed projects to determine the long-term viability of your investment.

Executing Your Laser Cutting Project

Once equipped with the right tools and designs, executing your laser cutting project effectively is the next step.

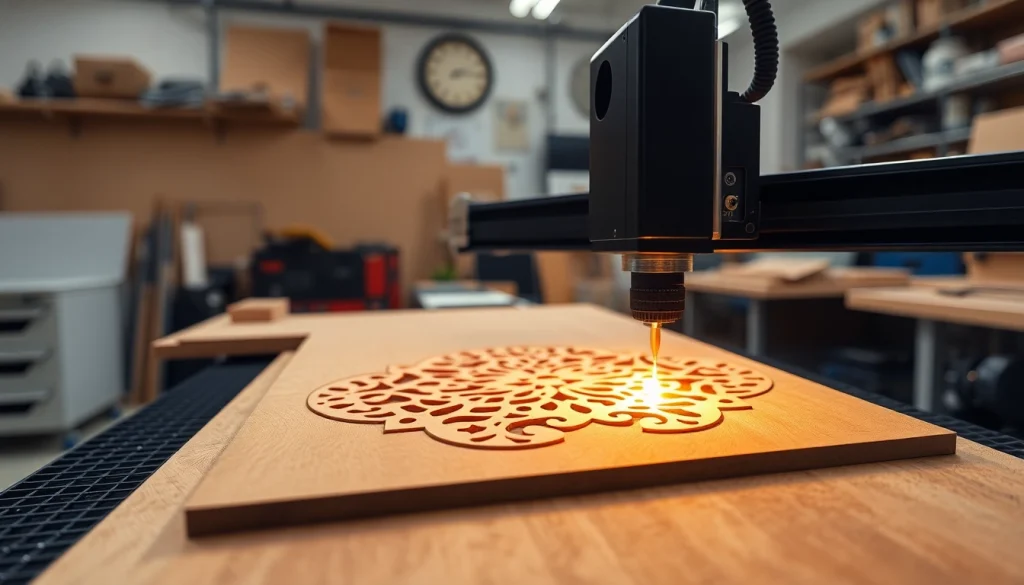

Step-by-Step Laser Cutting Process

- Prepare your workspace: Ensure it’s clean and organized for safety and efficiency.

- Set up the laser cutter according to the manufacturer’s instructions.

- Import your DXF file into the cutting software.

- Adjust settings based on the material you will be cutting.

- Run a test cut on scrap material.

- Finally, proceed with your final cut on the selected material.

Common Troubleshooting Tips

In the course of your project, you may encounter some problems. Here are solutions for common issues:

- Inaccurate Cuts: Check for misaligned settings or worn-out cutting heads.

- Material Burns: Reduce power settings or speed up the cutting speed to prevent scorching.

- Software Errors: Ensure your DXF file is compatible and correctly configured for your cutter.

- Mechanical Failures: Regularly inspect and maintain the machine for optimal performance.

Maintaining Your Laser Cutting Machine

Regular maintenance extends the lifespan of your laser cutting equipment and ensures high-quality results. Tips include:

- Cleansing Optics: Regularly clean the lenses and mirrors to avoid loss in performance.

- Inspect Components: Check for worn-out parts and replace as necessary to maintain cutting quality.

- Keep Software Updated: Ensure that your laser cutting software is up-to-date for optimal compatibility.

- Regular Calibration: Schedule training for staff to perform routine calibrations and adjustments.

Case Studies and Real-World Applications

Understanding the practical applications of DXF files in laser cutting can enhance your skills. Here are several case studies to highlight their effectiveness.

Success Stories Using dxf Files

Numerous businesses have successfully utilized DXF files for laser cutting, resulting in enhanced productivity and innovative products. For example, a small craft studio utilized DXF files to create intricate designs for custom wood products, increasing their output by 75% and reducing waste significantly.

Industry Trends and Innovations

With advancements in technology, the laser cutting industry is evolving rapidly. Innovations such as AI integration in design software are streamlining workflow, while eco-friendly materials are emerging as popular choices among consumers aiming for sustainable products.

Future of Laser Cutting Technologies

Looking ahead, the laser cutting industry is poised for growth. The integration of smart technology, automation, and enhanced materials will likely lead to new opportunities for manufacturers and creators. Embracing these trends is essential for staying competitive in the market.

Frequently Asked Questions

What is a dxf file?

A DXF file is a drawing exchange format that facilitates the transfer of design information between CAD software applications, enabling precise laser cutting.

How do I create a dxf file for laser cutting?

You can create a DXF file using CAD software like AutoCAD, Inkscape, or Adobe Illustrator by exporting your design in DXF format after finalizing it.

Can I use DXF files for 3D laser cutting?

Yes, DXF files can be used for 3D laser cutting. However, ensure that your design adequately reflects the depth and dimensions required for 3D operations.

What materials are best for laser cutting using DXF files?

Common materials include wood, acrylic, cardboard, and certain metals. The choice depends on your laser cutter’s capabilities and the specific project requirements.

How can I troubleshoot cutting errors with DXF files?

Double-check design accuracy, ensure proper file compatibility with the cutter, and evaluate machine settings or maintenance issues to troubleshoot cutting errors.