- Understanding Industrial Hydraulics Solutions

- Benefits of Implementing Industrial Hydraulics Solutions

- Choosing the Right Components for Industrial Hydraulics Solutions

- Common Challenges and Solutions in Industrial Hydraulics

- Future Trends in Industrial Hydraulics Solutions

- Frequently Asked Questions

Understanding Industrial Hydraulics Solutions

In the fast-paced world of manufacturing and industry, effective power transmission is paramount. Industrial hydraulics solutions play a crucial role in enhancing operational efficiencies, allowing industries to manage heavy loads and complex machinery with precision. This article delves deep into the nuances of industrial hydraulics, providing a comprehensive perspective on how these systems work, their benefits, and future trends.

What Are Industrial Hydraulics Solutions?

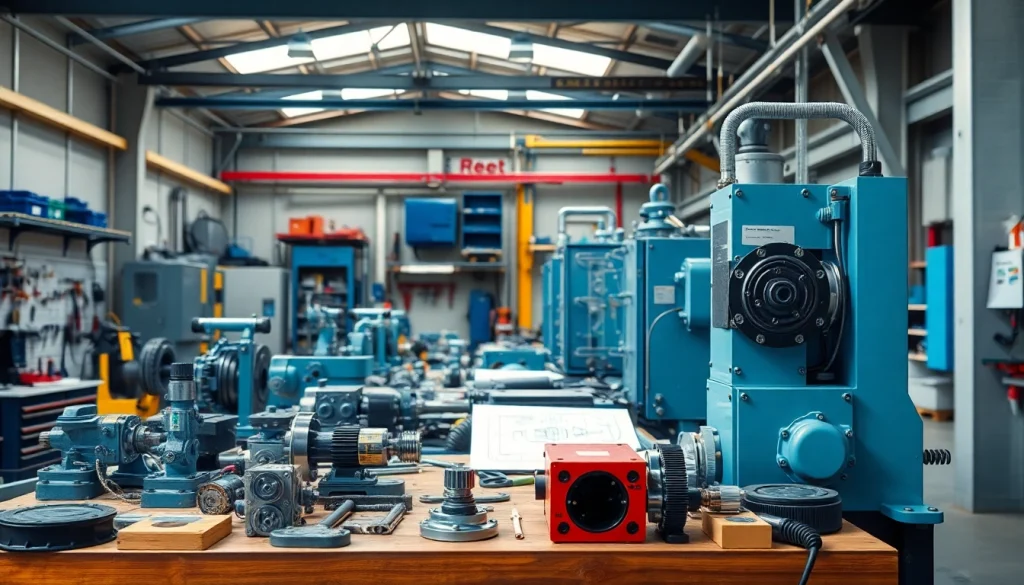

Industrial hydraulics solutions refer to systems that harness the power of pressurized fluid to drive machinery and equipment. By utilizing hydraulic fluid to transmit force, these solutions enable machines to perform heavy lifting, pushing, and other demanding tasks efficiently. Hydraulics systems typically include a range of components such as pumps, actuators, hoses, and valves that work together to create a responsive and powerful infrastructure.

The Basics of Hydraulic Systems

At the core of hydraulic systems is the principle of fluid mechanics. When hydraulic fluid is pressurized through a pump, it flows through pipes or hoses to actuators like cylinders or motors, resulting in controlled motion. Key components of a hydraulic system include:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy.

- Hydraulic Fluid: The medium through which power is transmitted, often oil-based.

- Actuators: Devices like cylinders that convert hydraulic energy back into mechanical energy.

- Control Valves: Regulate fluid flow and pressure to control system operation.

Understanding these components and how they interact is essential for effective implementation and maintenance of hydraulic systems.

Applications Across Industries

Industrial hydraulics solutions find applications in a wide array of industries, including:

- Manufacturing: Used in machinery for cutting, shaping, and assembling parts.

- Construction: Hydraulic excavators, cranes, and lifts rely on hydraulics for lifting, digging, and transporting.

- Aerospace: Used in systems requiring precise control and reliability, such as landing gear mechanisms.

- Agriculture: Hydraulic systems in tractors and combines facilitate heavy lifting and towing.

The versatility and power of hydraulic systems make them indispensable in these diverse fields.

Benefits of Implementing Industrial Hydraulics Solutions

Increased Efficiency and Productivity

One of the standout features of industrial hydraulics solutions is their ability to enhance efficiency. The power-to-weight ratio of hydraulic systems allows them to operate more effectively compared to mechanical systems. For example, hydraulic systems can provide significant force with relatively lightweight components, which ultimately reduces overall energy consumption.

Cost-Effectiveness in Operations

While the initial investment in hydraulic equipment can be substantial, the long-term operational savings can be remarkable. Hydraulic systems generally require less maintenance compared to mechanical systems, leading to lower repair costs. Furthermore, their durability and reliability reduce downtime, which can be a significant contributor to increased overall profitability.

Flexible Applications and Adaptability

Industrial hydraulics solutions are highly adaptable, making them suitable for various applications and environments. They can be fine-tuned to meet specific operational needs, such as adjusting the speed and force of movement. This flexibility allows businesses to maximize their machinery capabilities across different tasks.

Choosing the Right Components for Industrial Hydraulics Solutions

Key Components Explained

Selecting the appropriate components is critical for the success and longevity of hydraulic systems. Key components include:

- Hydraulic Pumps: Choice depends on the desired flow rate and pressure required for the application.

- Filtration Systems: Essential for maintaining fluid cleanliness and preventing contamination.

- Correct Hoses and Fittings: These must match the fluid type and pressure ratings to ensure safety and performance.

How to Select Quality Parts

Opting for high-quality components is paramount for the reliability and efficiency of hydraulic systems. Key considerations when selecting parts include:

- Manufacturer Reputation: Choose established brands known for quality and performance.

- Material Durability: Ensure components can withstand the operating environment without failure.

- Warranty and Support: Look for products that come with a robust warranty and customer support.

Ensuring Compatibility in Systems

Compatibility among components is essential for effective operation. Mismatched hydraulic parts can lead to reduced efficiency, increased wear, and even catastrophic failure. When integrating new components into existing systems, perform thorough compatibility checks on pressure ratings, flow rates, and physical connections.

Common Challenges and Solutions in Industrial Hydraulics

Identifying System Failures

Hydraulic systems are subject to various failures, including leaks, overheating, and system malfunctions. Regular monitoring and diagnostic checks can help identify issues before they escalate. Common signs of system failure include unusual noises, sudden drops in pressure, or erratic actuator movement.

Regular Maintenance Practices

Maintaining hydraulic systems involves routine checks and servicing. Recommended practices include:

- Regularly changing hydraulic fluid to prevent contamination.

- Inspecting seals and hoses for wear and leaks.

- Conducting pressure tests to ensure the system operates within safe limits.

Upgrading Existing Systems

As technology advances, upgrading hydraulic systems can lead to enhanced performance,

reliability, and efficiency. Evaluate current systems to identify potential improvements, research newer technologies, and consider incorporating automation features that can significantly boost operational capabilities.

Future Trends in Industrial Hydraulics Solutions

Automation and Smart Systems

The future of industrial hydraulics is closely tied to automation and smart technology integration. Systems equipped with sensors and IoT capabilities can provide real-time data analysis, enabling predictive maintenance, improved operational control, and enhanced energy management. Automation allows for precise control, streamlining processes, and reducing human error.

Sustainability in Hydraulic Technologies

There is a growing emphasis on sustainability within the hydraulic industry. Companies are exploring biodegradable hydraulic fluids and developing systems that consume less energy, thus reducing their environmental footprint. Implementing green practices not only benefits the environment but can also improve a company’s competitive edge.

Emerging Technologies Impacting the Industry

Innovative technologies like electric-hydraulic systems, advanced materials, and AI-driven analytics are set to revolutionize industrial hydraulics solutions. These technologies can enhance system performance, offer greater flexibility, and reduce the operational costs associated with traditional hydraulic systems.

Frequently Asked Questions

What are industrial hydraulics solutions?

Industrial hydraulics solutions refer to systems that utilize pressurized fluid to power machinery and equipment in various industries.

What are the benefits of hydraulic systems?

Hydraulic systems enhance efficiency by providing high power with less weight, allowing for precise control and reduced operational costs.

How do I maintain my hydraulic systems?

Regular checks for leaks, changing fluids as recommended, and inspecting key components are essential for effective maintenance.

What are common issues in hydraulic systems?

Common issues include leaks, overheating, and contamination, which can lead to reduced performance or failure.

What is the future of industrial hydraulics solutions?

The future of industrial hydraulics involves automation, smart technologies, and a focus on sustainability to improve efficiency and reduce environmental impact.